Equipment

|

|  |  |

|

|

|

|

|  |  |  |

|

|  |  |

|  |  |  |

|

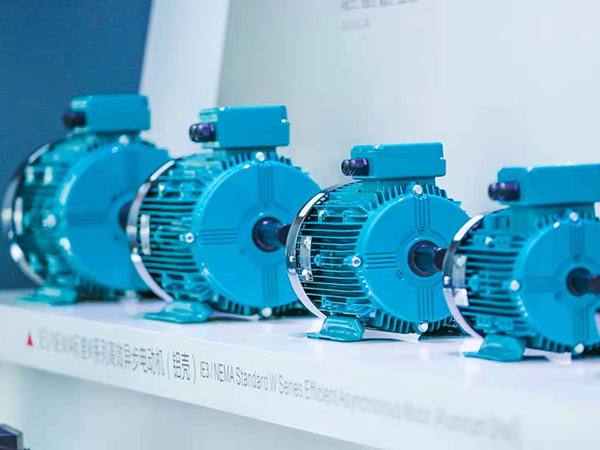

Exhibition

|  |  |

|  |  |

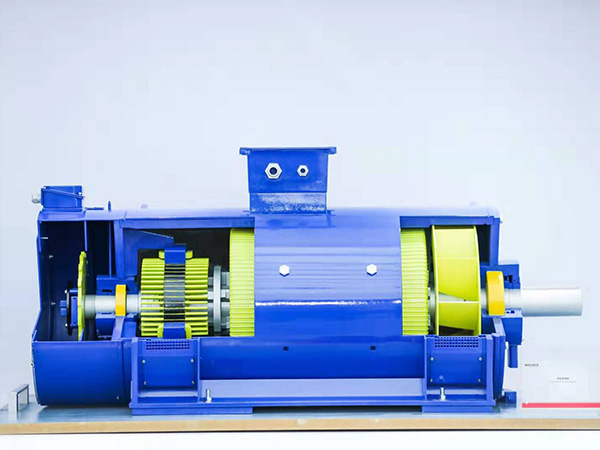

(Rotor)

The rotor employs a squirrel cage design, primarily utilizing cast aluminum rotors. These rotors are produced through centrifugal casting or die-casting, where molten aluminum is poured into the rotor core's slots, forming a single-piece structure that integrates rotor bars and end rings. The robust construction and manufacturing process of cast aluminum rotors ensure reliability and excellent torque characteristics. For larger motors, copper bar rotors are used, benefiting from secure bar fastening and reliable end ring welding. Additionally, high-speed motors often incorporate protective rings to further enhance the reliability of copper bar rotors.

(Stator)

The coils are meticulously crafted using polyester film and glass cloth insulation. To enhance electrical and mechanical properties, the coils are impregnated with either low-powder or medium-powdered mica tape. The VPI (Vacuum Pressure Impregnation) process ensures optimal insulation and durability.

(Frame)

Leveraging a fully digital platform, the motor frame is designed through advanced structural and fluid multi-physics field simulations. Adhering to the original patent's structure and design, the frame is constructed using high-strength cast iron (or steel) and exhibits exceptional structural redundancy, heat dissipation capabilities, and vibration isolation. This robust design ensures superior mechanical shock resistance, low vibration levels, and reduced temperature rise, resulting in reliable and efficient motor operation.

(Low Noise Fan Hood System)

The low-noise fan cover system features a compact, lightweight design that minimizes vibration. Its side-mounted air inlet optimizes airflow, reducing noise and ensuring efficient ventilation, even in tight spaces. The system incorporates sound-absorbing materials to further reduce noise levels. The IP22 rating guarantees user safety by preventing accidental contact with the fan.

Personnel Operation Process

|  |  |  |

|  |

|

|

|

|

|

|

|

|

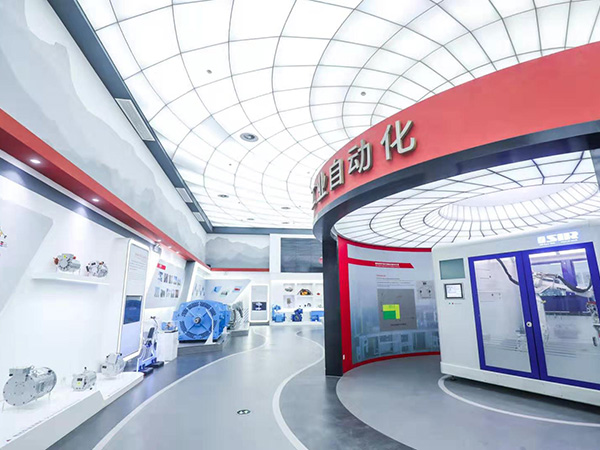

Wolong Exhibition Hall

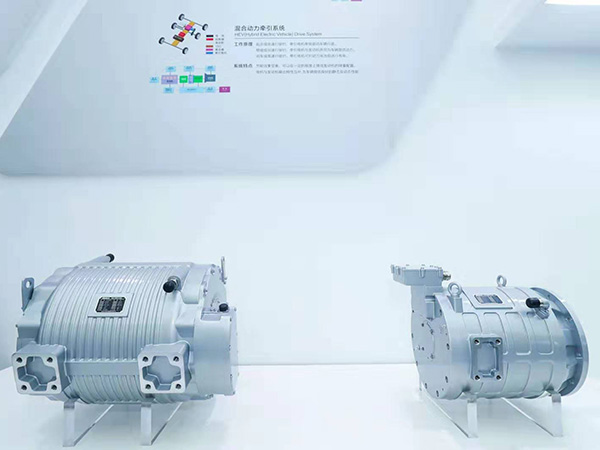

Motor Model

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |

Exhibition Hall

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |